Moving Energy Forward

Case Studies

Preparing Remediation after Refinery Shutdown

Gunvor ceased refining operations in Antwerp amidst the COVID-19 crisis and, as mentioned in a previous issue of the report, operated the Antwerp site since then as a tank storage location. The site was fully shutdown on 31 December 2022 and is being prepared for its next life. An important element of the preparation is soil and groundwater remediation.

When Gunvor purchased the refining assets in Antwerp in 2012 the due diligence carried out at the time showed contamination of soil and groundwater under the previous ownership, which is very typical for refinery sites in use since the 1960s. Gunvor entered an agreement with OVAM, the Flemish regulator for soil and groundwater pollution, to take responsibility for the historic pollution and provide a surety for future remediation.

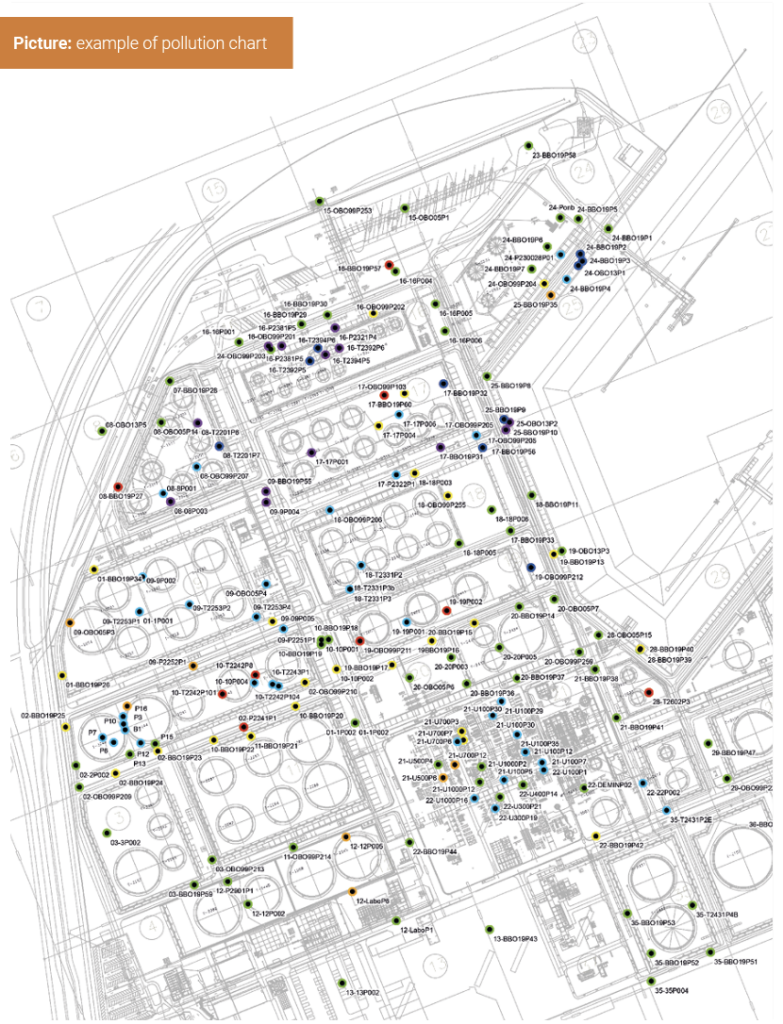

Gunvor hired soil investigation specialists to map the contaminated plots in detail and assess the environmental risks. This resulted in reports with analytical results and detailed maps of the contaminants, predominantly oil constituents, in the various ground and groundwater layers.

As a next step, a soil remediation plan was developed for the spots for which remediation is most urgent, based on the risk assessment. These are some spots alongside the harbour and jetties, where there is a possibility that oil migrates into the surface water.

Key Results

In 2020, 94 trades were assessed (covering 6.80 million tonnes of LNG), and 122 in 2021 (covering 8.02 million tonnes). The emissions are broken down according to source, assets, and destination countries, with temporal analyses (quarterly and annual). Results include:

This plan has been submitted to OVAM and has been approved. The plan will be executed with the support of specialised remediation contractors.

The plan consists of some special features:

- The revetment alongside the shore of the harbour will be renewed with a system to capture oil floating on the groundwater. The oil further away from the edge will be extracted by means of multiple phase vacuum extraction. That is a system that extracts a suspension of soil vapours, water and oil from the ground. As the refinery owns a wastewater treatment plant and a vapour recovery unit, both of which would be very useful in the remediation process, the plan is to utilise these units as far as possible, but this is dependent on the redevelopment plans of the new owner.

- Another interesting feature is pumping back extracted groundwater. During the investigations it was discovered that not only oil constituents but also PFAS (Poly Fluorinated Alkyl Substances) are present in the groundwater. PFAS is extremely difficult to remove from water because it hardly absorbs into anything and is very persistent (no biodegradation). When the groundwater has passed the water treatment unit to remove the oil, it still contains PFAS. Recycling this (partly) into the ground, will prevent the discharge into the Antwerp harbour waters. We still need to check that this recirculation does not affect the extent of the PFAS contamination elsewhere on the site.

A further remediation project will be started in parallel to clean up the ground under the refinery units when these are decommissioned and demolished.